1.tsiaj cobkev taw qhia

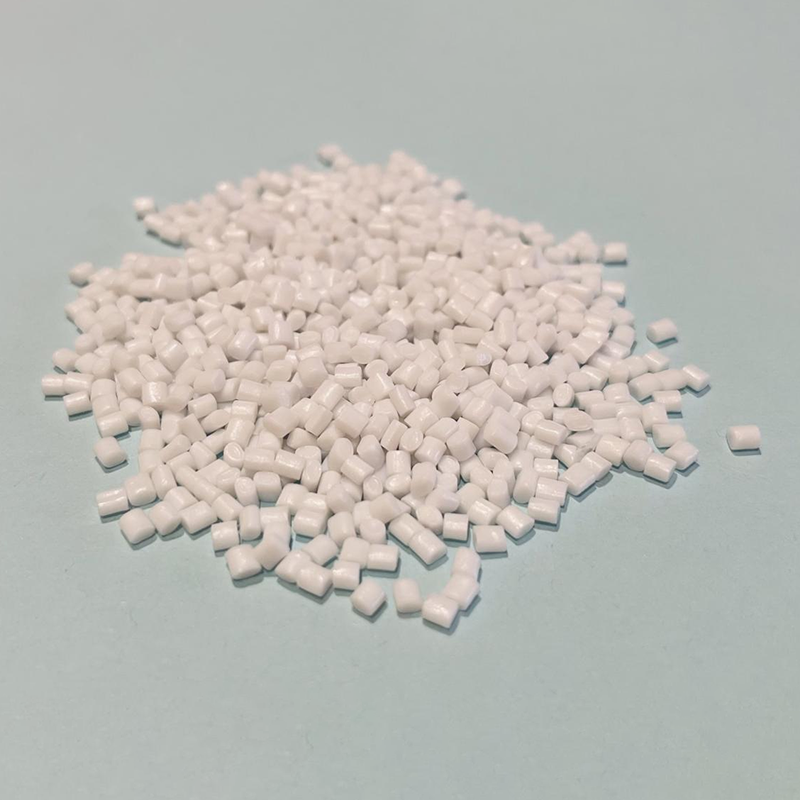

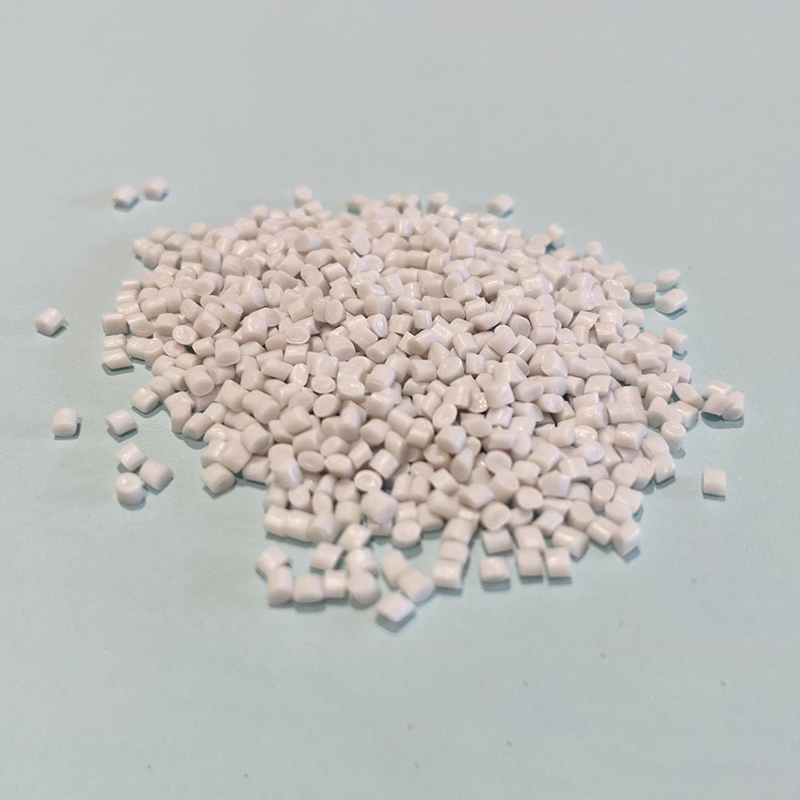

PET tshuaj npe Polyethylene terephthalate, tseem hu ua polyester, tshuaj formula COC6H4COOCH2CH2O.Dihydroxyethyl terephthalate tau npaj los ntawm kev hloov pauv ntawm dimethyl terephthalate nrog ethylene glycol lossis esterification ntawm terephthalate nrog ethylene glycol, thiab tom qab ntawd cov tshuaj tiv thaiv polycondensation.Nws yog crystalline saturated polyester, milky dawb los yog lub teeb daj, crystalline polymer nrog du thiab glossy nto.Nws yog ib hom resin hauv lub neej thiab tuaj yeem muab faib ua APET, RPET thiab PETG.

PET yog mis nyuj dawb los yog lub teeb daj, crystalline polymer nrog ib tug du, ci ntsa iab.Nws muaj cov khoom zoo ntawm lub cev thiab cov khoom siv hauv ntau qhov kub thiab txias, siv lub sijhawm ntev txog li 120 ℃, rwb thaiv tsev hluav taws xob zoo heev, txawm tias qhov kub thiab txias ntau zaus, nws cov khoom siv hluav taws xob tseem zoo, tab sis tsis zoo corona kuj, creep kuj, qaug zog kuj, kev sib txhuam tsis kam, qhov ntev stability yog zoo heev.PET muaj ester daim ntawv cog lus, decomposition yuav tshwm sim nyob rau hauv qhov kev txiav txim ntawm muaj zog acid, muaj zog alkali thiab dej chav, tsis kam mus rau organic solvents, zoo huab cua kuj.

2.resin zog

PET muaj kev ua haujlwm zoo, qaug zog ua haujlwm, kev sib txhuam thiab kev ruaj ntseg, me me thiab siab hardness, thiab muaj qhov hnyav tshaj plaws hauv cov thermoplastics: cov hluav taws xob rwb thaiv tsev zoo, kev cuam tshuam me ntsis los ntawm qhov kub thiab txias, tab sis tsis zoo corona kuj.Tsis muaj tshuaj lom, huab cua tsis kam, kev ruaj ntseg zoo tiv thaiv cov tshuaj, tsis muaj dej nqus, tsis muaj zog acids thiab cov kuab tshuaj organic, tab sis tsis kub resistant dej immersion, tsis alkali tsis kam.

PET cobNws muaj qhov hloov pauv ntawm iav siab, qeeb crystallization tus nqi, lub voj voog ntev molding, lub voj voog ntev molding, loj molding shrinkage, tsis zoo seem stability, brittle crystallization molding, tsis tshua muaj kub tsis kam.

Los ntawm kev txhim kho cov nucleating agents thiab crystallizing agents thiab iav fiber reinforcement, PET muaj cov yam ntxwv hauv qab no ntxiv rau cov khoom ntawm PBT.

1. Thermal deformation kub thiab kev siv lub sij hawm ntev yog qhov siab tshaj plaws hauv cov thermoplastic general engineering plastics.

2. Vim tias muaj kev kub siab ua haujlwm, qhov kev txhim kho PET yog impregnated rau 10S nyob rau hauv lub solder da dej ntawm 250 ° C, yuav luag tsis muaj deformation los yog discoloration, uas yog tshwj xeeb tshaj yog haum rau kev npaj ntawm hluav taws xob thiab hluav taws xob qhov chaw rau solder vuam.

3. Lub zog dabtsi yog khoov yog 200MPa, lub elastic modulus yog 4000MPa, lub creep kuj thiab qaug zog kuj zoo heev, lub hardness ntawm nto yog siab, thiab cov neeg kho tshuab zog zoo ib yam li thermosetting plastics.

4. Txij li thaum tus nqi ntawm ethylene glycol siv los tsim PET yog yuav luag ib nrab ntawm butanediol siv los tsim PBT, PET resin thiab reinforced PET yog tus nqi qis tshaj ntawm engineering plastics thiab muaj tus nqi siab.

Txhawm rau txhim kho PET cov khoom, PET tuaj yeem ua tau zoo nrog PC, elastomer, PBT, PS chav kawm, ABS, PA.

PET (txhim kho PET) feem ntau yog ua tiav los ntawm kev txhaj tshuaj molding, thiab lwm txoj hauv kev suav nrog extrusion, tshuab moulding, txheej thiab vuam, sealing, machining, nqus txheej thiab lwm yam txheej txheem thib ob.Qhuav kom huv si ua ntej sib sau.

Polyethylene terephthalate yog npaj los ntawm transesterification ntawm dimethyl terephthalate nrog ethylene glycol lossis esterification ntawm terephthalate nrog ethylene glycol, thiab tom qab ntawd cov tshuaj tiv thaiv polycondensation.Nws yog crystalline saturated polyester, qhov nruab nrab molecular hnyav (2-3) × 104, qhov piv ntawm qhov hnyav nruab nrab rau tus lej nruab nrab molecular hnyav yog 1.5-1.8.

Cov iav hloov pauv kub 80 ℃, Martin tshav kub tsis kam 80 ℃, thermal deformation kub 98 ℃ (1.82 MPa), decomposition kub 353 ℃.Nws muaj cov khoom siv kho tshuab zoo heev.Siab rigidity.High hardness, me me dej nqus, zoo seem stability.Zoo toughness, cuam tshuam tsis kam, txhuam tsis kam, creep kuj.Cov tshuaj tiv thaiv zoo, soluble hauv cresol, concentrated sulfuric acid, nitrobenzene, trichloroacetic acid, chlorophenol, insoluble hauv methanol, ethanol, acetone, alkane.Ua haujlwm kub -100 ~ 120 ℃.Khoov zog 148-310MPa

Kev nqus dej 0.06% -0.129%

Kev cuam tshuam lub zog 66.1-128J / m

Rockwell hardness M 90-95

Elongation 1.8% -2.7%

3. kev siv tshuab

PET kev ua haujlwm tuaj yeem yog txhaj tshuaj molding, extrusion, tshuab moulding, txheej, sib txuas, machining, electroplating, nqus kub plating, luam ntawv.Cov hauv qab no feem ntau qhia ob yam.

1. Txhaj theem ① kub qhov chaw: nozzle: 280 ~ 295 ℃, pem hauv ntej 270 ~ 275 ℃, nruab nrab forging 265 ~ 275 ℃, tom qab 250-270 ℃;Screw ceev 50 ~ 100rpm, pwm kub 30 ~ 85 ℃, amorphous pwm yog 70 ℃, rov qab siab 5-15KG.② Kev sim dehumidification tshuab, cov khoom siv kub 240 ~ 280 ℃, txhaj tshuaj siab 500 ~ 1400 ℃, txhaj tshuaj molding kub 260 ~ 280 ℃, ziab kub 120 ~ 140 ℃, siv sijhawm 2 ~ 5 teev.

2. Nyob rau hauv zaj duab xis theem, PET resin yog hlais thiab ua ntej qhuav los tiv thaiv hydrolysis, thiab tom qab ntawd cov amorphous tuab daim ntawv yog extruded nyob rau hauv lub extruder ntawm 280 ° C los ntawm T-pwm, thiab lub nruas txias los yog coolant yog quenched rau khaws cia rau hauv daim ntawv amorphous rau tensile orientation.Daim ntawv tuab yog tom qab bidirectional ncab los ntawm tenter los tsim ib zaj duab xis PET.

Longitudinal stretching yog preheat cov ntawv tuab rau 86 ~ 87 ℃, thiab ntawm qhov kub no, ncab li 3 zaug raws li qhov txuas ntxiv ntawm daim ntawv tuab, kom nws txoj kev taw qhia tuaj yeem txhim kho qib ntawm crystallization kom ncav cuag qhov kub siab dua: transverse preheating kub ntawm 98 ~ 100 ℃, tensile kub ntawm 100 ~ 120 ℃, tensile piv ntawm 2.5 ~ 4.0, thiab lub thermal qhov chaw kub ntawm 230 ~ 240 ℃.Cov zaj duab xis tom qab ntsug thiab kab rov tav stretching kuj yuav tsum tau kub-zoo li tus kom tshem tawm cov zaj duab xis deformation los ntawm stretching thiab ua ib zaj duab xis nrog zoo thermal stability.

Post lub sij hawm: Sep-05-2023